Friday, May 26

Bungs, Bungs and more Bungs

I think I've worn the patience of my co-workers thin in my discussion of bungs, though they were a bit humored. When I told them I needed to find a flat bung plug and a bung wrench, I got some strange looks, and was asked to repeat what I'd just said. However, it got worse when I tried to explain that the bung plug I needed had to be flat so I could drill out the bung plug, insert a pipe into the bung plug, weld around the pipe, screw it into the bung hole, plumb in the piping, and then pump grease into the bung plug pipe. I guess if I'd had a picture of what I was trying to accomplish, it would have been easier.

Sunday, May 21

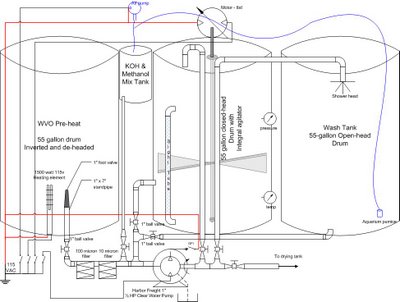

Initial design - Appleseed inspired

With any luck, I'm only 2-3 weeks from having my processor setup. Which is good, since my WVO supply is kicking out 30-40 gallons a week! I've included a picture of my draft plans. Click on the picture to see it magnified. It's currently in Visio.

Comments on some of my design decisions:

1) I can't weld, so can't fix-up a discarded water tank. I also don't want to spend $220 on a new water tank, so I've decided to forego a water-heater tank and go with a 55-gallon drum with built-in agitator. I added the built-in agitator to compensate for my smallish pump, and to permit me to process batches of up to 40 gallons WVO at a time, but also accomodate 10-gallon batches if I so choose. By using both agitation and circulation, it should mix my processing tank nicely.

2) I'm wondering about going pure gravity feed for the methanol/KOH mix.

3) I'm not sure if I'll want to put additional valves on the filters to isolate them, so there would be valves both upstream and downstream from the filters, while keeping them serial.

4) There are a few fuzzy details on my design:

a) agitator motor - will likely be salvage motor from the first major appliance I see by a curb, or a drill.

b) methanol tank - to process batches of 40 gallons, I'd need an 8-gallon tank. I've got lots of 10-gallon drums I could use, but then I can't see when the methanol is mixed up. Serially-linked carboys perhaps? I'm still working on an economical solution for the methanol tank, suggestions welcomed. (Sure $46 HDPE carboys are easy to suggest, but that'd be over $100 with shipping!)

c) agitation of methanol tank - if I wind up using a 10-gallon closed drum, how to agitate, and how to ensure the mix is mixed?

d) wash tank - would I need to heat the wash tank?

e) distillation of methanol - how to recover the precious methanol from the glycol byproduct?

As you can see, several more questions to be addressed in the design.

Tuesday, May 16

Processor Component: Pump plus other stuff

I've been looking around at pumps, and have found contradictory advice. Some homebio enthusiasts swear by the 1" Chicago Electric clear water pump at Harbor Freight, as a reliable and cheap solution for a home processor, while other websites say it's underpowered. Fortunately, Biodiesel guru Girl Mark clears the waters and says that this pump is suitable for Appleseed processors of up to 100 liters, but advises a bigger pump or 1" plumbing to process larger batches. Sold! I found one at Harbor Freight tonight on sale for $25, and only $20 after 20% coupon.

Since I have 1" plumbing, thanks to a great deal on 1" ball valves at Home Depot ($3.90 ea), and am planning on using an agitator in my processing tank, I figure this pump will be sufficient for batches up to 40 gallons, if I should so choose. Of course, this is pure conjecture, and I doubt I'll often make batches over 20 gallons, but it's comforting to think that I should be able to go to near capacity on my 55-gallon drum, since I'm not just relying on the pump for agitation.

I also found a deal on 8 330-lb capacity wheels, which should combine nicely with the 10 scrap 2x4's i nmy garage to make a dandy processing platform

I also discovered that a) if you wear flip-flops to get the b) afore-mentioned 1" ball valves out of your trunk, noting that c) said ball valves weigh about a pound each, and then d) the bag rips, then e) you'll dance up and down on the other foot and be tempted to use foul language.

Thursday, May 11

Girl Mark teaching in Columbus

This just in, from the Cool Stuff Department -- Girl Mark will be

coming to Columbus to teach a biodiesel workshop this fall, likely

October. This will be very cool, and a great kickstart to the MidOhio

Biofuels Co-op. With any luck, we will have 1-2 mobile processors by

then, and can create quite an event out of this.

Wednesday, May 10

WVO pickup kicking off

I'm getting real activity with starting my biodiesel processing, and it looks like things are picking up steam at last. OK, not steam, make that WVO. I found 10-gallon drums at Container Management in Columbus, and they seem like real nice folks. I was a little bummed that the containers weren't power washed before I picked them up, but one of their new truck drivers had clipped an electric pole, and they were without power for a few hours, so I forgive. My employer seemed very happy with the solution, as it's clean and convenient. I'm hoping I can find some way to transport the drums -- they won't safely fit in my Jetta. :-(

Thursday, May 4

My First Columbus Biofuels Meeting

We met at Planks in German Village tonight to discuss our goals for the Columbus Biofuels Co-Op (or whatever we're going to name this thing). It felt good to drive my TDI there, even if I am still burning petro-diesel :-(

Over weak beer and good company, we pounded out some initial objectives:

Over weak beer and good company, we pounded out some initial objectives:

- Establish WVO pickup routes, teams, and processing methods.

- Storage and facilities to support same.

- Collaborative mobile processing plant for demonstrations, GTG, fairs, schools, whatever

- Create a co-operative organization that aids members in achieving what we cannot as individuals

- Act as an advocate in Central Ohio for viable renewable fuels, in particular biodiesel and ethanol production

- Collaborate and liaise with government, other co-ops, corporations and others